Spheroidal iron, which is also referred to as ductile cast iron or nodular cast iron, is a distinct type of cast iron that has been integrated in modern manufacturing and engineering and has become popular in the industry. Compared to cast iron, which is usually considered to be brittle, spheroidal iron is significantly tough, ductile, and durable.

The focus of this article is to explain the main components of spheroidal iron, its properties, main applications, as well the the benefits which encourage its usage in different industries.

What Is Spheroidal Iron?

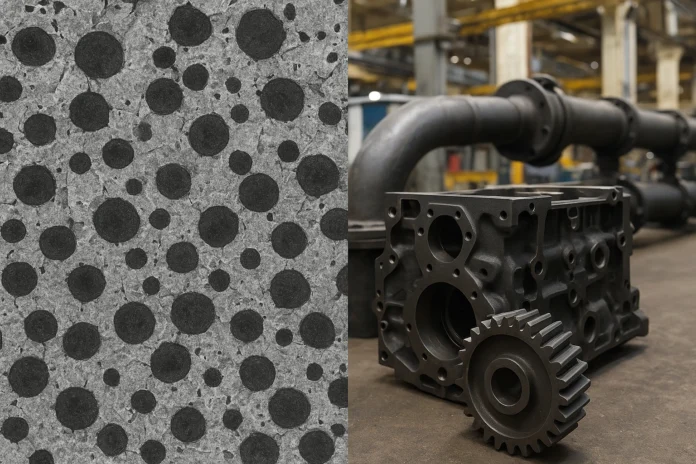

Spheroidal iron is a variety of cast iron in which the graphite content is present in the form of small spheres, or nodules, rather than flakes. The nodular form of graphite is produced when small quantities of magnesium or cerium are added during the molten stage of the metal, which alters the structure of the graphite.

Because the graphite particles are not rugged, rather rounded, spheroidal iron is noted for providing better mechanical strength, shock resistance, and flexibility when compared to traditional grey cast iron.

More commonly referred to as:

- Ductile cast iron

- Nodular cast iron

- SG iron (Spheroidal Graphite Iron)

Important Characteristics and Properties

The specific microstructure of spheroidal iron gives it several important physical and mechanical properties:

High Strength

Spheroidal iron possesses tensile strength of 400-700 MPa, far exceeds that of grey cast iron. This allows spheroidal iron to endure substantial load without fracture.

Excellent Ductility

Spheroidal iron, unlike brittle cast iron, is able to bend-deform without rupture under stress. Its elongation of 10-25% enables it to act as a shock absorber and damp absorber of vibrations.

Corrosion Resistance

This material has good resistance to corrosion, particulaly when alloyed with nickel and chromium.

Wear Resistance

This material is ideal for parts that endure friction and abrasion due to its microstructure and hardness.

Good Machinability

The ease with which spheroidal iron can be machined enables the production of complex and precision-engineered parts.

Vibration Dampening

The reduction of vibration brought about by the nodular graphite is advantageous for parts used in engines and heavy machinery.

The Steps Involved in Producing Spheroidal Iron

The spheroidal iron production process comprises various sub-processes:

- Melting: The base iron is melted in a furnace.

- Nodulizing Treatment: Small amounts of magnesium or rare earth elements are added to alter the form of the iron’s graphite.

- Inoculation: Additional elements are added to improve the microstructure.

- Casting: The molten iron is poured into molds to form the shapes required.

- Cooling and Solidification: The cooling processes are controlled to ensure that the spherical graphite form is preserved.

- Machining and Finishing: The cast product is machined to specific requirements.

Common Uses of Spheroidal Iron

The additional flexibility and strength that is provided to spheroidal iron is highly used in the automotive, construction, water supply and heavy engineering industries.

Automotive Industry

- Engine blocks

- Crankshafts

- Axles

- Suspension components

Spheroidal Iron’s capacity to absorb vibrations also assist in the reduction of noise and wear in vehicle components

Pipeline Systems

- Water and sewage pipes

- Gas pipelines

- Fittings and valves

Spheroidal Iron is also used in the transport of various fluids due to its long service life and corrosion resistance.

Machinery Components

- Gearboxes

- Housings

- Bearing caps

The use of spheroidal iron in these components allows them to benefit from increased wear resistance and improved machinability.

Construction

- Bridge supports

- Structural components

Spheroidal iron is renowned for its capability to support heavy loads and resist environmental damage.

Agriculture and Mining

- Plowshares

- Drill bits

- Conveyor components

Its resilience to rough conditions makes it useful in abrasive environments.

Benefits of Using Spheroidal Iron

Aside from its remarkable strength, spheroidal iron has many additional benefits.

Cost-Effectiveness

Spheroidal iron is more economical than steel, in that it offers comparable mechanical properties.

Long Service Life

Lower wear and corrosion leads to longer-lasting components, which in turn reduces maintenance expenses.

Versatility

From small machine components to large infrastructural projects, it has a wide range of applications.

Energy Efficiency in Production

Due to steelmaking not being utilized, in the case of spheroidal iron’s casting process, this makes it a more environmentally sound option.

Safety and Reliability

For applications where structural strength is a necessity, its lack of sudden failure under stress makes it safer.

Spheroidal Iron vs Grey Cast Iron

Characteristic Spheroidal Iron Grey Cast Iron

- Graphite Structure Spherical (nodules) Flake

- Strength High Moderate

- Ductility Excellent Low

- Shock Resistance High Low

- Machinability Good Good

Typical Applications Automotive, pipelines, bridges Stove parts, machine bases

Maintenance and Care for Spheroidal Iron Products

Even though spheroidal iron is strong, spheroidal iron products benefit from the following care measures:

- Scrutinize for incipient cracks and wear in heavily loaded applications.

- Weather-resistant coatings for surfaces exposed to harsh and corrosive weather conditions.

- Lubricants for joints to reduce friction.

- Active measures to reduce the accumulation of debris or rust.

Environmental Impact and Sustainability

As with other products, spheroidal iron has the advantage of being fully recyclable making it an environmentally sound choice for industries seeking to improve their waste footprint. The casting method of production is not only energy efficient, further optimally reducing carbon emissions.

Final Thoughts

Spheroidal iron is an example of advanced materials. It strongly competes with traditional materials like cast iron and steel. Its applications in automotive, pipelines, and construction demonstrates the versatility of modern materials.

By evaluating properties, benefits, and applications, industries can make educated decisions to optimize performance, endurance, and value over time.

FAQs

Q: Where is spheroidal iron commonly utilized?

Due to its strength and flexibility, spheroidal iron is utilized in automotive components and pipelines, as well as in machinery parts and construction components.

Q: Spheroidal iron and ductile iron, are they different?

Spheroidal iron and ductile iron are indeed the same; the name change is purely based on the spiral shaped graphite.

Q: What is the reason to spheroidal iron strength than grey cast iron?

Spheroidal iron’s strength and ductility comes from its spherical graphite nodules which resist the

Q: Does spheroidal iron have the ability to resist corrosion?

Yes, spheroidal iron can resist corrosion especially if it is alloyed with nickel or chromium.

Q: What is the method of manufacturing spheroidal iron?

Spheroidal iron is produced by adding magnesium or certain rare earth metals to molten cast iron which alters the graphite form from flakes to nodules.